We have significant experience investigating refractory and refractory structures that fail, do not perform as intended or simply for peace of mind/verification.

We can perform the following advanced analysis:

-

Heat Transfer Analysis

-

Stress Analysis

-

Dynamic Analysis

-

Thermodynamic analysis

-

Computational fluid dynamics (CFD)

We can solve problems:

- failure analysis of refractory structures

- failure analysis of refractory anchors

- failure analysis of acid brick

- chemical attack of refractories

- advanced material quality analysis (chemistry, mineralogy and physical properties)

- process reactions with refractories

Palmer Technologies is frequently engaged as an expert to analyse the failures of refractories (fibres, monolithic, brick) structures or refractory materials for chimneys, ladles, reactors, furnaces, boilers, calciners, reformers, kilns, SRU’s and FCCC units.

Examples

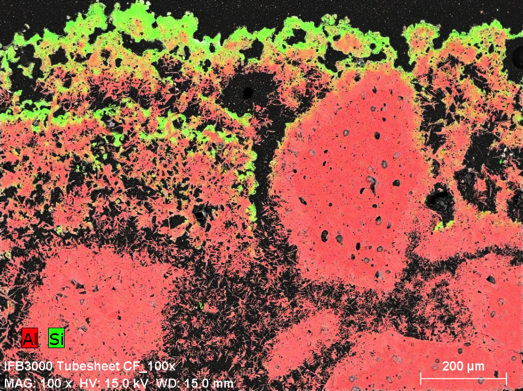

Flint Hill Resources USA

Fouling of Boiler Tubes

Flint Hill Resources engaged Palmer Technologies to investigate the cause of boiler tube fouling in their Sulphur Recovery Unit. In particular, if it was caused by reactions of the process gases with the refractory or some other mechanism.

Palmer Technologies carried out an in-depth analysis using chemical, physical and thermodynamic analysis techniques to determine the mechanism.